To continue providing quality products that meet the needs and expectations of our customers and consumers to achieve their total satisfaction, it is essential to innovate constantly, both in our products and services, as well as in our procedures, with the objective of increasing efficiency and maintaining our position at the forefront of the market, generating greater value, and driving up growth for both the organization and society.

Based on the inherent characteristics of our products and services, our innovation strategy focuses mainly on the following areas:

PRODUCT QUALITY AND SAFETY

To maintain the quality and safety that distinguish our products, we have a culture of excellence based on a robust and well-established quality system which includes the BQS Corporate Quality Policy, where we lay down our commitment and our guidelines to produce products of the highest quality, always striving to ensure the welfare of our customers and always meeting their needs and expectations to maintain their trust and preference, through a process of ongoing improvement.

Therefore, Grupo Bafar is driven by the following Quality Metrics:

- Measurement and analysis of customer and consumer complaints

- Supplier management with compliance results above 85%

- Audits at plants with compliance results above 90%

- Products ranking as 1st and 2nd preference in the market

- Measurement of the maturity level of Lean tools that allow us to ensure the ongoing improvement of the organization’s performance through different management approaches

Additionally, we have set the following strategic objectives to be met across all our business activities and operations:

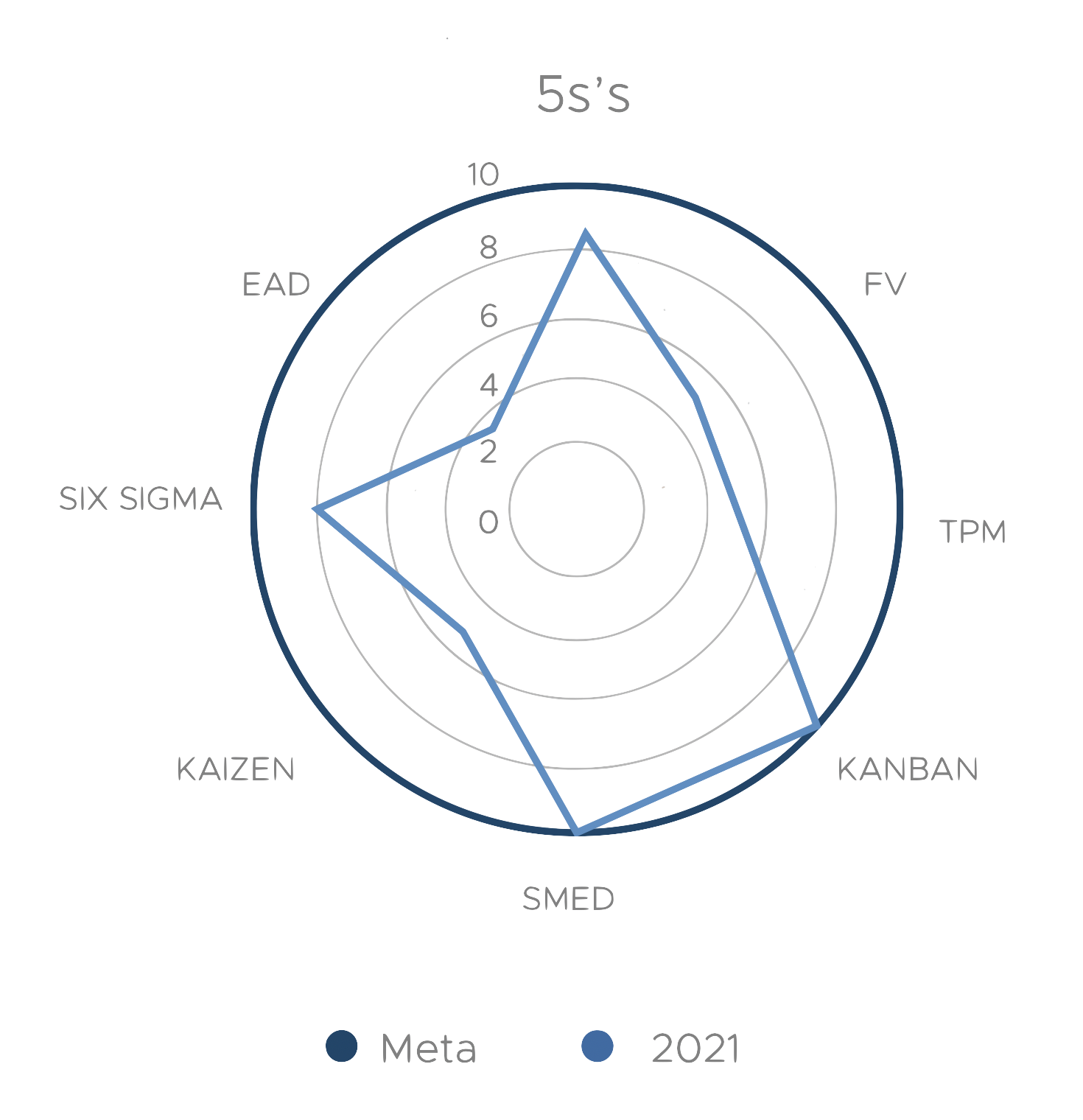

Maturity level and Lean culture

As one of our main quality tools, we analyze on a quarterly basis the maturity level of different Lean activities implemented in our production processes. These activities include:

- The 5S’s: they seek to eliminate unnecessary elements, order work tools, clean workspaces, standardize classification, order, and cleanliness measures, and create habits so that employees adopt the above measures.

- Visual factory (VF): emphasizes the need to display critical information specifically in the physical workspaces where it is needed, through signage, labels, posters, and display cases, among others. This promotes a safer and more efficient work environment by eliminating the need for repetitive training and constant supervision.

- Total productive maintenance (TPM): each worker independently inspects and operates his or her equipment, taking responsibility for reporting any deviation from normal operation to solve problems promptly.

- Single Minute Exchange of Die (SMED): integrates internal measures, such as cleaning, assembly and start-up of machinery, and external measures, such as planning and training, to shorten downtime between batches produced.

- Kaizen: by using Deming’s continuous improvement cycle, collaborators’ creativity is encouraged to improve the operation and efficiency of production processes.

- Kanban: consists of doing only what is needed, when it is needed and in the optimum quantity to speed up production.

- Six Sigma: this is a management methodology that seeks to minimize production defects to a maximum value of 3.4 defects per million units produced.

Annual result of the maturity level assessment of the Chihuahua plant

PRODUCT LIFE CYCLE

The product life cycle spans from raw material procurement, production and packaging to distribution, sale, and final disposal. All the information on the product life cycle is currently managed through an automatic documenting and monitoring system. However, in the future we are looking for a more robust, automatic, secure, and reliable tool adapted to the trends and needs of the sector, including the analysis of environmental metrics.

During 2021, Grupo Bafar’s innovation efforts focused mainly on packaging technology to minimize environmental impact, align with the legal provisions to reduce the consumption of single-use plastics, and offer our customers products tailored to their needs.

We carried out four main innovation projects in 2021:

1. Production line of sausages offered in modified atmosphere multipacks: “Split and fresh”

This project focused on the packaging of Sabori brand products in detachable bipack and tripack presentations. The objective was to create packages with a rigid bottom and flexible resealable film, allowing the consumer to measure their consumption with four sausages per pack in such a way that the products could be stored for a longer period of time while maintaining their freshness.

2. Production line of aged and sliced meats offered in high vacuum and modified atmosphere packs

To increase the diversity of products in the market, as well as the renewal of the PARMA brand, this project focused on the design of a new automated slicing line for aged products offered in high vacuum and modified atmosphere packs featuring high-quality printed and esealable elements. These new packages and presentations allow the consumer to portion the product and maintain freshness. Additionally, the vacuum- packed products have a secondary high-quality printed carton package to achieve a competitive and attractive packaging design in the market.

3. Expansion of the production line and portfolio of “Delicharola” aged meats and cheeses

Given the success and high demand for the “Delicharola” line and with the intention of offering consumers the experience of tasting high-quality dairy and meat products, a production line of aged meats and cheeses was developed at the La Piedad plant. This project sought to develop a product in which cheeses and meats are sliced and arranged in a circular fashion in an attractive package, mimicking a tray ready for consumption without the need to be placed in a different tray.

4. Expansion of the production line of sliced cold meats at the La Piedad plant (federally certified TIF 126)

Due to the growth in demand for sliced cold meats, Grupo Bafar carried out a project to expand the presentations of the sliced products line at the La Piedad plant, offering consumers high-vacuum and modified atmosphere packaging with the same designs as the Chihuahua plant to share manufacturing volumes and meet demand.

HEALTH, WELL-BEING AND NUTRITION

The health, well-being and nutrition of our consumers is at the heart of the development of our products. For this reason, we evaluate all our products to ensure that they comply with the profile and requirements according to their intended role within each brand and with the applicable Mexican Standards related to nutritional balance, caloric intake, and food industry standards.

Our commitment to health and well-being ranges from supporting families to nourish their children and fostering habits and awareness of the importance of good nutrition through the selection of raw materials, the offering of nutritionally balanced products, and communication centered on these aspects.

As a clear example of this commitment to the health, well-being and nutrition of society, the Sabori brand follows a holistic and well-being approach geared towards generating a positive impact through good habits and a healthy diet, in addition to encouraging consumers to engage in physical activity through communication on multiple digital platforms and at several sale points.

To further our efforts and commitments to health and well-being, we developed the Sabori’s “Al Natural” line product. This line is exempt from complying with the NOM-051 labeling standard as it is the only product of its kind free of monosodium glutamate (MSG), artificial preservatives, nitrites, phosphates, or gluten in the Mexican market.

Additionally, in this line we also offer the sausage with the highest protein content in the market and a turkey breast with 18% fat-free protein, obtaining the highest “Extrafine” classification.

To continue innovating and keeping in line with consumer food trends and preferences, we are developing a line of Sabori vegetarian products with a sufficiently robust nutritional value to provide consumers with all the necessary nutrients and to meet the brand’s objective of safeguarding the health and well-being of its consumer.