GRI 302-1, 302-3, 303-3, 303-4, 305-1, 305-2, 305-4, 306-2, 306-3, 306-4, 306-5

At Grupo Bafar, the eco-efficiency of our operations is core to our sustainability strategy; therefore, in 2021 we began by mapping our consumption and impacts in terms of energy, emissions, water, waste and biodiversity

This initial measurement is our steppingstone to launch an action plan and monitor indicators that will allow us to manage the environmental performance of our business units in an adequate and consistent manner.

ENERGYAs part of our sustainability strategy, measuring the energy consumption of Grupo Bafar’s business units is a first step that will later allow us to implement actions to optimize and minimize energy and fuel consumption.

For Grupo Bafar, the integral well-being of our collaborators, clients, and communities where we operate is closely bound to the care of the environment; for this reason, we promote the transition towards cleaner and renewable energy sources through our B-Energy cogeneration power plant.

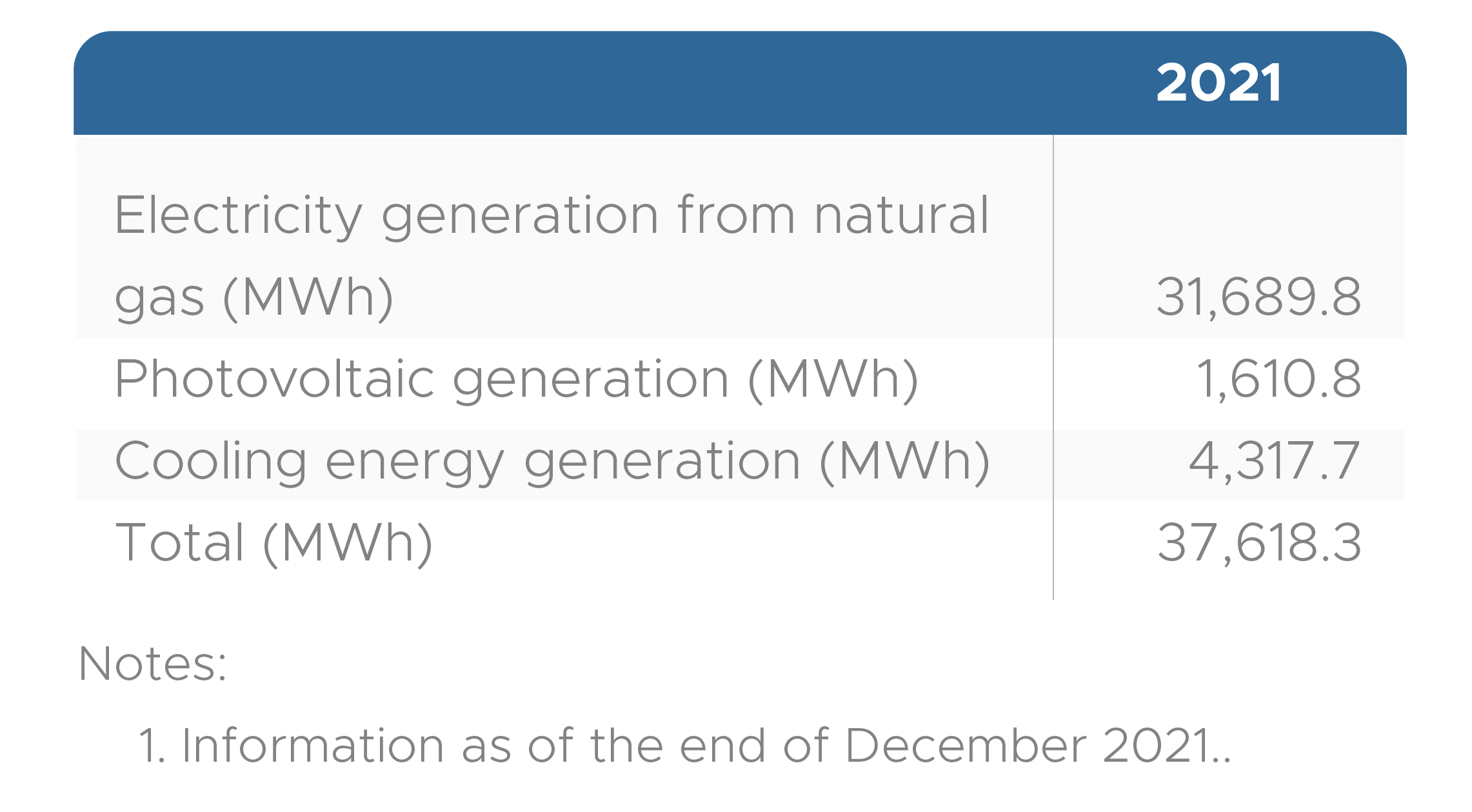

Besides generating electricity from natural gas. The plant provides photovoltaic and cooling energy that is used in the production processes of our Chihuahua plant.

The Retail business unit consumed 1,610.8 MWh of electricity generated through solar panels in 2021.

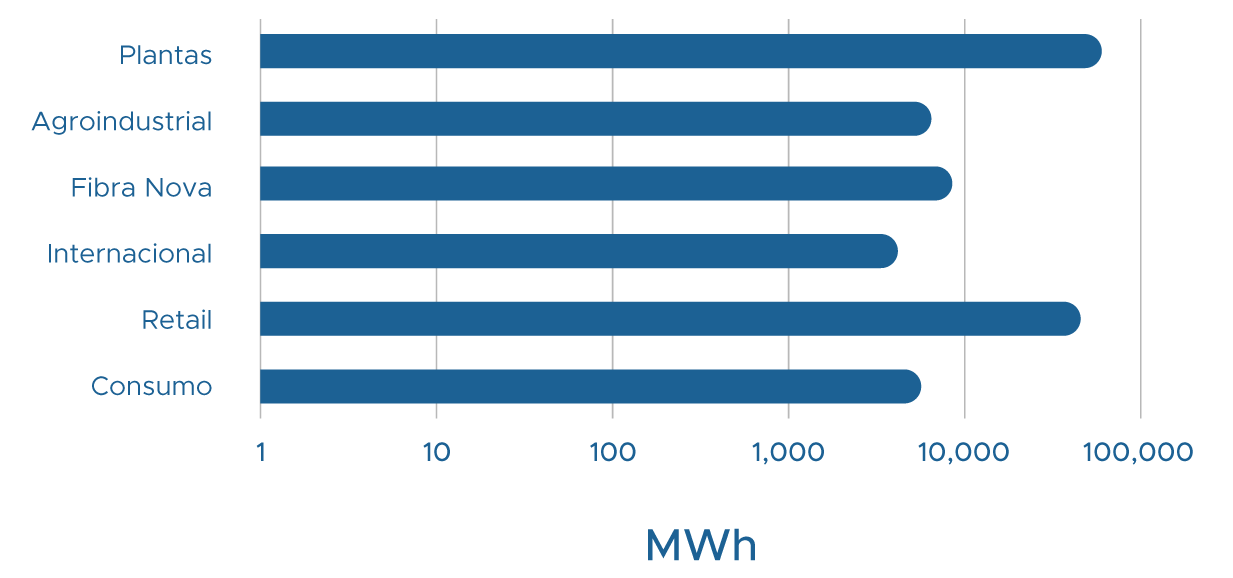

Electricity consumption by business unit (MWh)

In 2021, we consumed 138,105 MWh of electricity for the operation of our different business units and the B-Energy power plant. This consumption was supplied both by the electricity generated in our cogeneration plant and by the Mexican power grid.

Notes:

- Information as of the end of December 2021.

- Vextor’s electricity consumption is included in the consumption of the Chihuahua plant as they share the same location.

- For Fibra Nova:

- •Fibra Nova’s energy consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

- • Electricity consumption of one property was as of the end of August 2021.

- • Six sites include data as of the end of September 2021.

- •Two sites include data as of the end of October 2021.

- •Five sites include data as of the end of November 2021

- In addition to the electricity consumption by business unit, the B-Energy plant consumed 24.6 MWh for its operations in 2021.

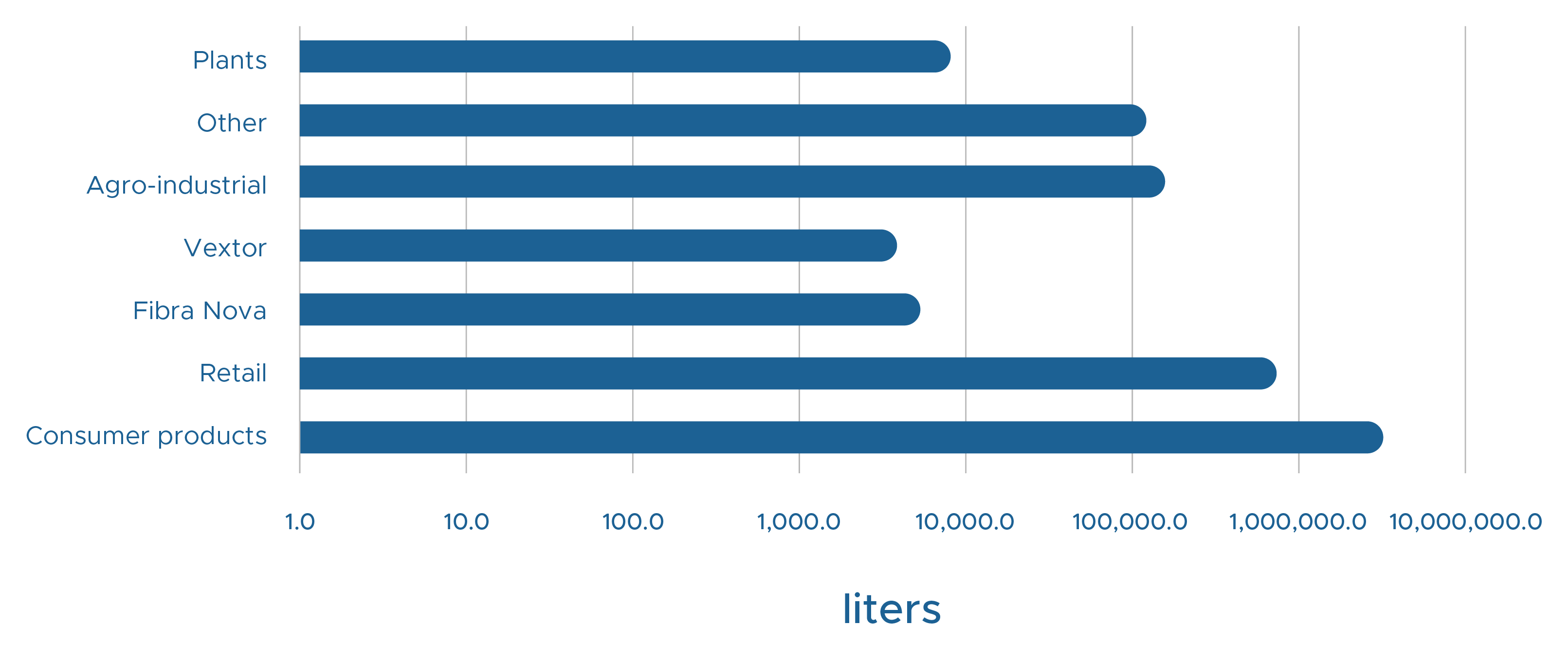

Fuel consumption by business unit

Regarding fuels, our energy sources come from gasoline, diesel, natural gas, and LPG.

Gasoline consumption

In 2021, we consumed 3,770,162.07 liters of gasoline.

Notes:

- International business unit has zero gasoline consumption.

- Fibra Nova’s energy consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

Diesel consumption

Our diesel consumption was 4,505,029.73* liters in 2021.

*An 850 kg/m3 density was used to calculate the volume of diesel consumed in plants.

Notes:

- Vextor and the international business unit had zero diesel consumption in 2021.

- Fibra Nova’s energy consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

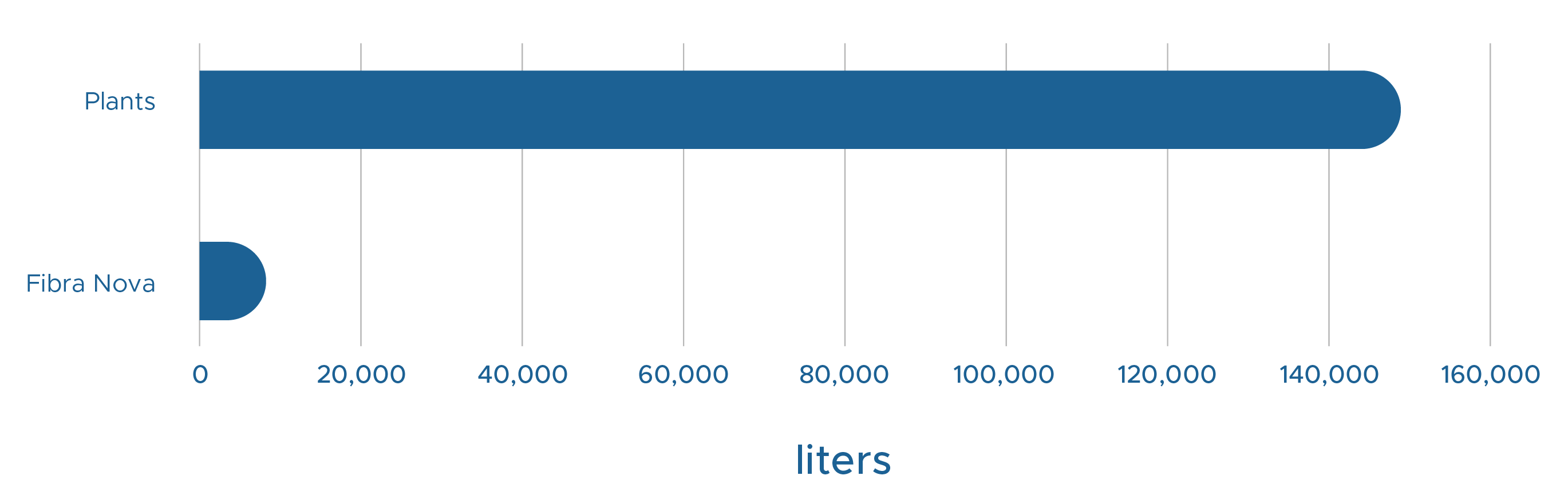

LPG consumption

Grupo Bafar consumed 157,603.20 liters of LPG during the year.

Notes:

- Fibra Nova’s energy consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

- LPG was only consumed in Fibra Nova’s plants and properties in 2021.

Natural gas consumption

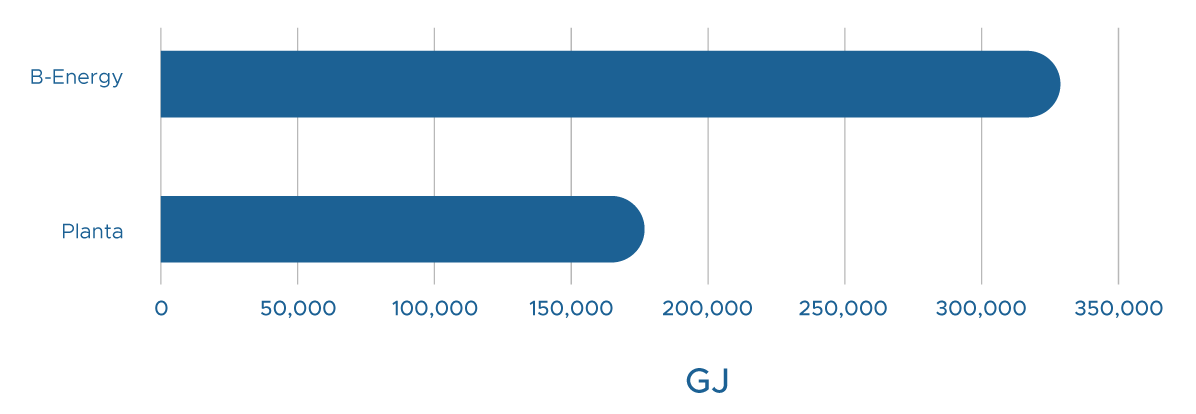

In 2021, the International business unit, Fibra Nova, the plants and the B-Energy cogeneration power plant jointly consumed 508,722.39 GJ of natural gas; more than 65% of this consumption was from B-Energy

Notes:

- Information as of the end of December 2021.

- In 2021, the International business unit and Fibra Nova natural gas consumption was 52.36 GJ and 1,092 GJ, respectively.

- Fibra Nova’s energy consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

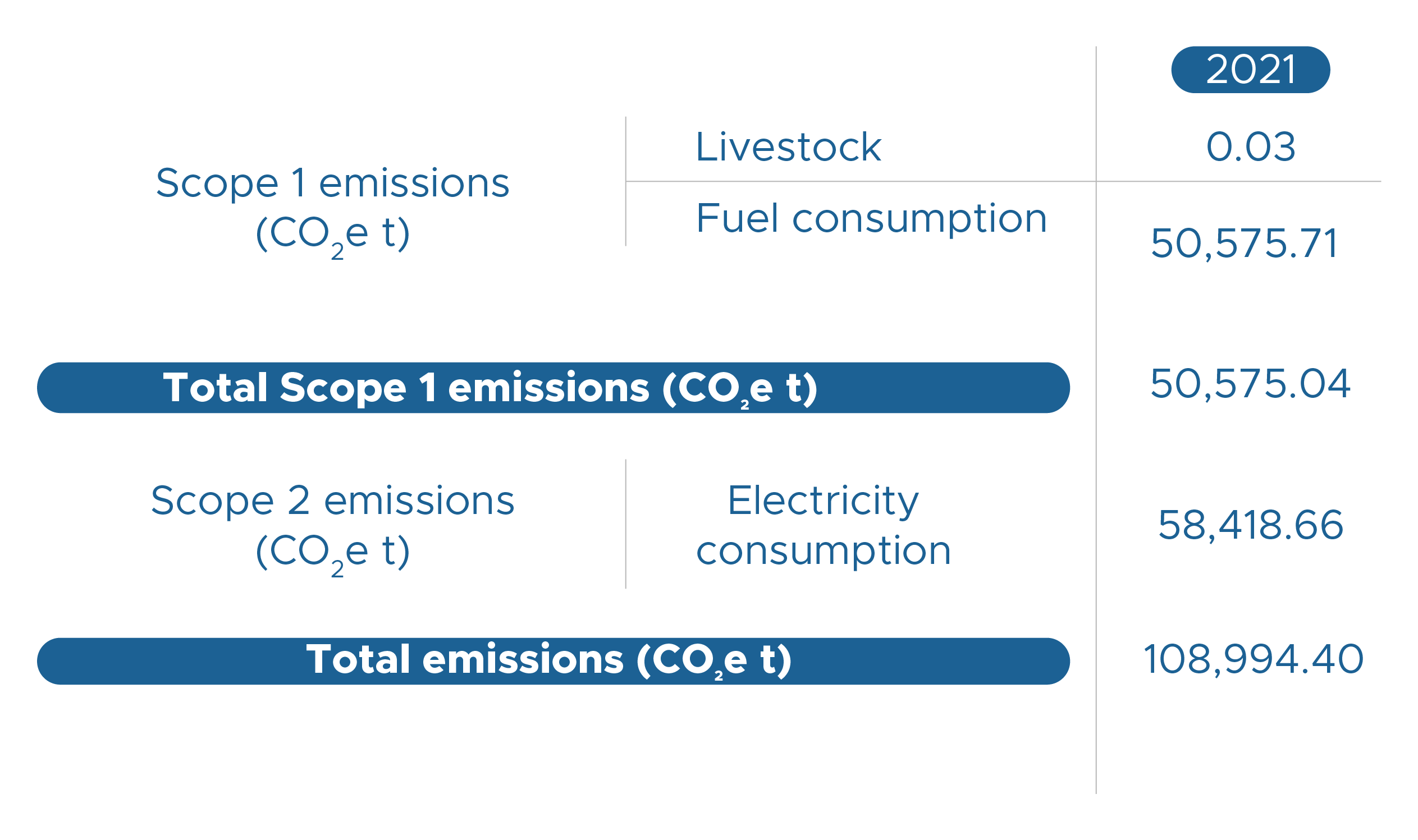

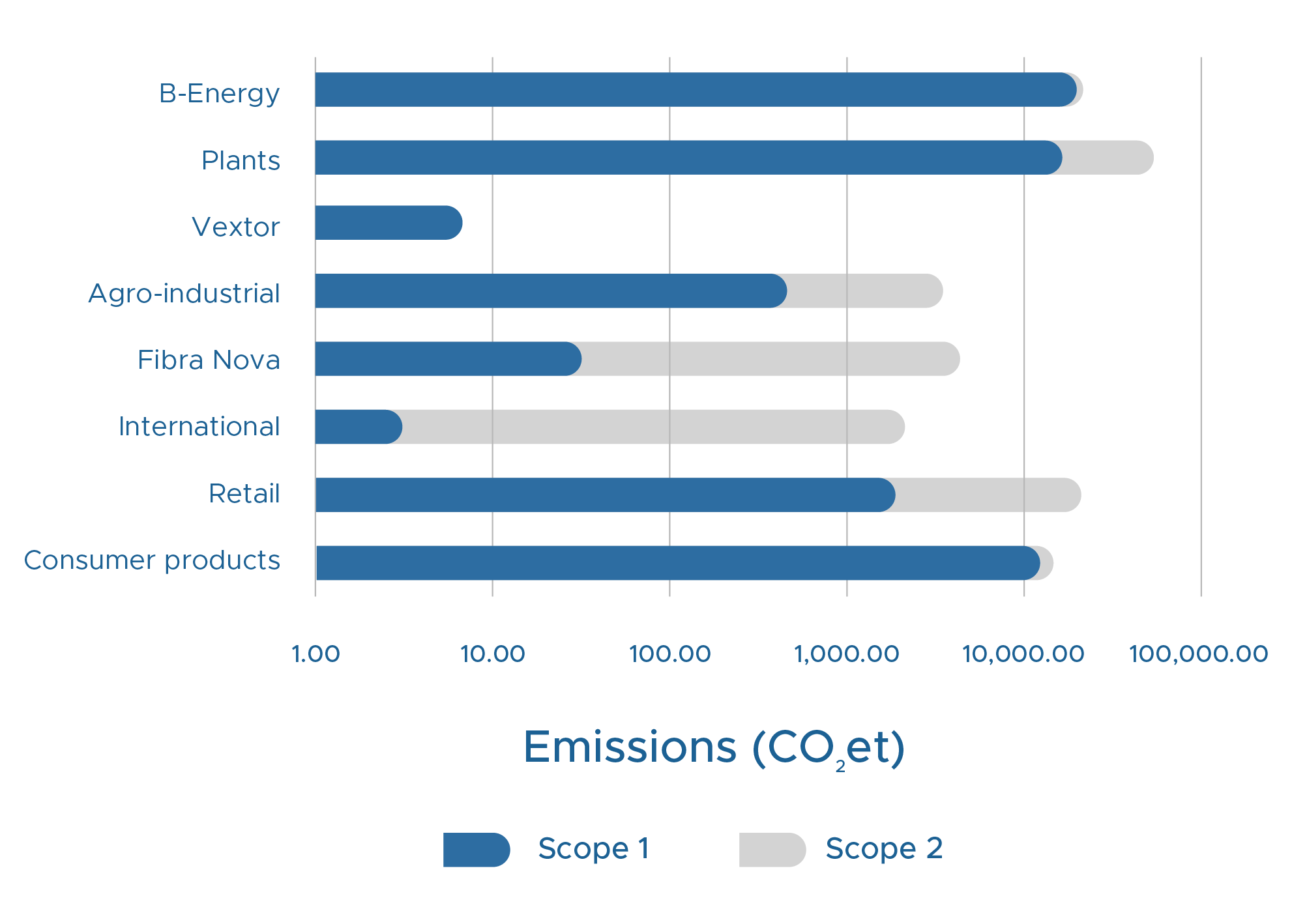

EMISSIONS

Emissions from our operations come from both direct and indirect sources. Our Scope 1 emissions include livestock from our agro-industrial business line and our fuel consumption, while our Scope 2 emissions come from our electricity consumption.

Notes:

- Information as of the end of December 2021.

- The calculation of Scope 1 emissions considered 173 head of cattle from livestock management in the agro-industrial business unit.

- Fuel consumption includes natural gas, LPG, gasoline, and diesel used in Grupo Bafar’s business units and in the cogeneration plant during 2021.

- Scope 1 emissions were calculated in accordance with the reporting methodology of the National Emissions Registry, approved by Mexico’s Secretariat of Environment and Natural Resources (Secretaría de Medio Ambiente y Recursos Naturales, SEMARNAT for its Spanish acronym), together with the appropriate calorific values, emission factors, and global warming potentials.

- Scope 2 emissions were calculated considering Mexico’s 2021 grid emission factor (published by SEMARNAT).

Notes:

- Information as of the end of December 2021.

- The calculation of Scope 1 emissions considered 173 head of cattle from livestock management in the agro-industrial business unit.

- Scope 1 emissions were calculated in accordance with the reporting methodology of the National Emissions Registry, approved by Mexico’s Secretariat of Environment and Natural Resources (Secretaría de Medio Ambiente y Recursos Naturales, SEMARNAT for its Spanish acronym), together with the appropriate calorific values, emission factors, and global warming potentials.

- Scope 2 emissions were calculated considering Mexico’s 2021 grid emission factor (published by SEMARNAT).

- Vextor’s Scope 2 emissions are included in total Scope 2 emissions as they share the same location, and the electricity consumption of both units is consolidated.

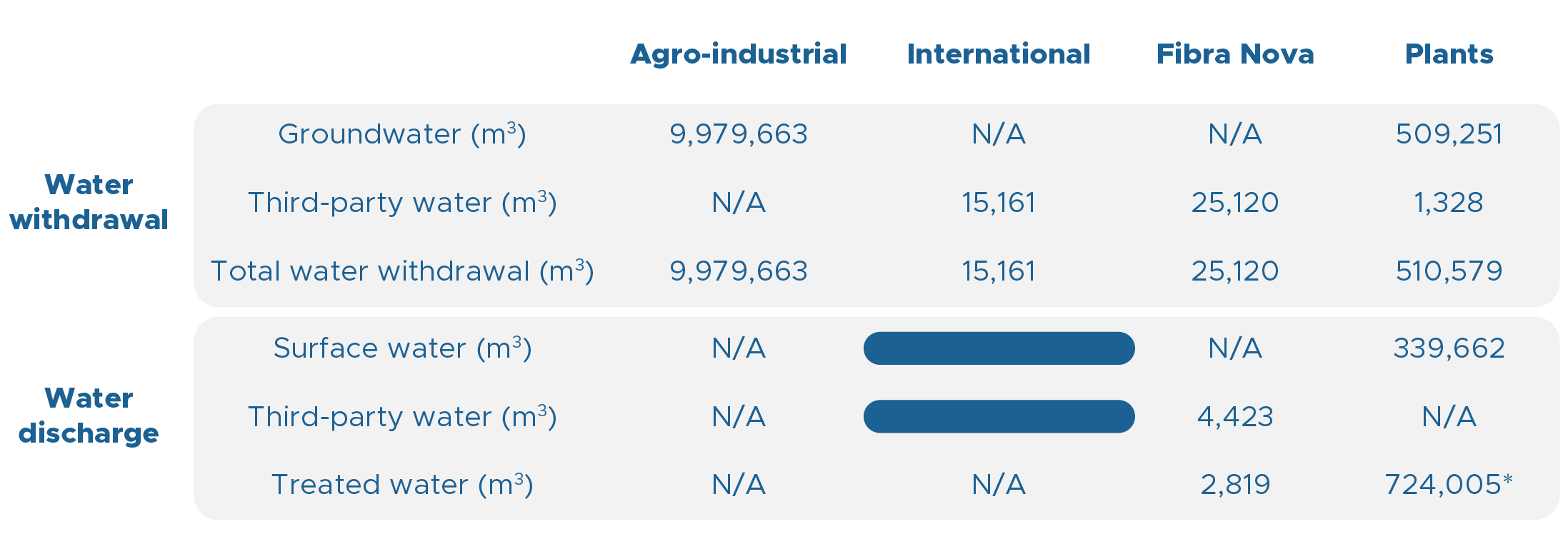

WATER

To track our impact on water bodies, we monitor and record hourly water consumption and discharge through flowmeters installed in different wells and discharge points of our plants. This information, applicable to certain business units, is shared on a quarterly basis with the National Water Commission (Comisión Nacional del Agua, CONAGUA for its Spanish acronym)

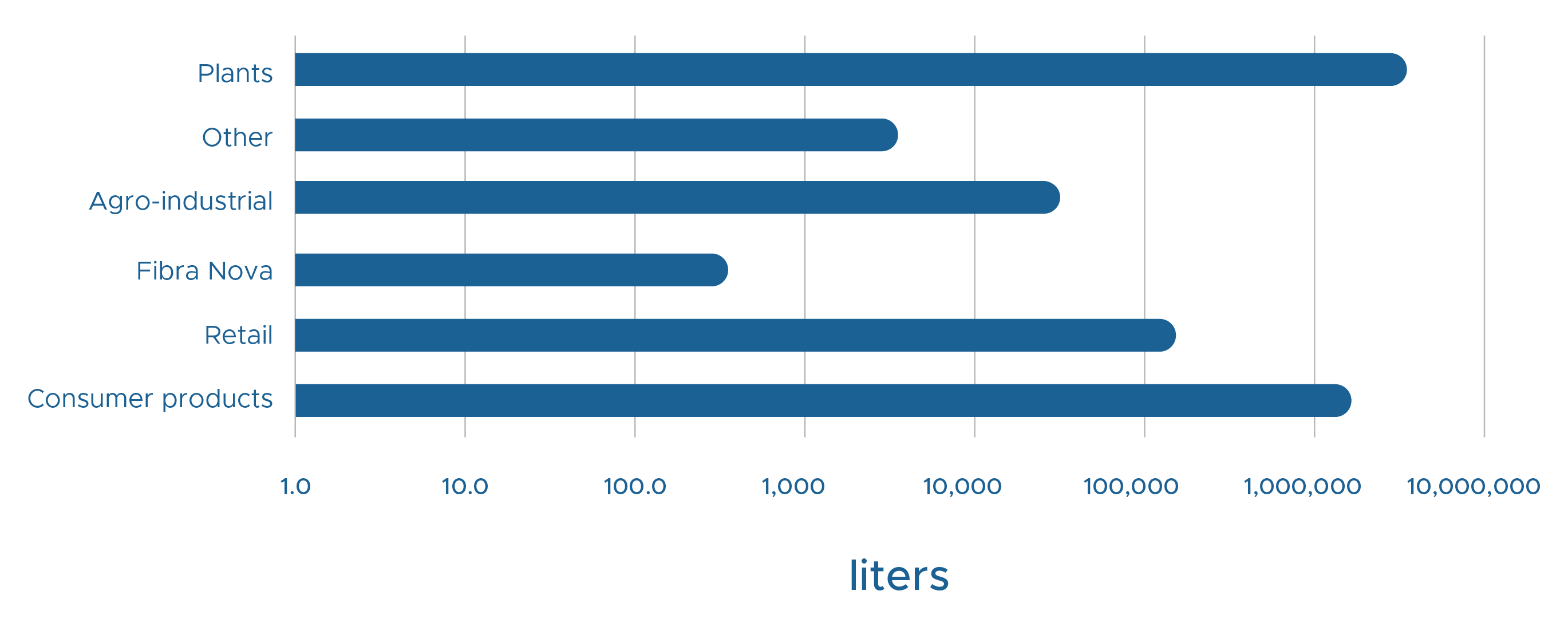

Water consumption by business unit:

Notes:

- Information as of the close of December 2021.

- Vextor’s water consumption is included in the consumption of the Chihuahua plant as they share the same location.

- Fibra Nova’s water consumption is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

- The volume of water treated by Fibra Nova is the amount of water that is treated by third parties (private suppliers or government).

- We do not have information on the water discharge of the International unit, as well as the water withdrawal and discharge of the Consumer Products and Retail business units; however, we are working on consolidating this data.

On the other hand, we seek to develop measures and initiatives that allow us to maximize the responsible use of water. As part of our goal of preserving natural resources, the wastewater treatment plant at the Chihuahua plant allows us to reuse the treated water from the effluents of the continuous ovens, cooking area and breading area, to use it for the irrigation system of the plant’s green areas, as well as for the cooling systems of the production process.

In addition, we have put in place several initiatives that will enable us to reduce water consumption by 30%. Among these actions are the control of high-pressure washing systems handled by maintenance staff to restrict access to water only on the days and times when washing is performed, and the installation of hoses and spray nozzles for these systems.

In the Agro-industrial division, recognizing the importance of water resources for production, we have promoted various initiatives to modernize and automate our irrigation systems. This modernization, throughout the entire production process, allows us to make efficient use of water, improve production and pecan quality per hectare, while reducing energy consumption, as follows:

Withdrawal

We have a system that allows us to image and monitor groundwater levels to avoid overexploitation and efficiently use water. Sensors are used to measure the levels and flows of the water table, as well as to monitor the amount of water withdrawn from the wells, measuring the volume, and recording its depletion throughout a cycle.

Water supply

Reservoirs are used to achieve more efficient distribution to different distances and flow requirements. The reservoirs have ultrasonic sensors that monitor water levels, interacting with the wells to turn them on and off automatically.

Overpumping

The irrigation system modernization allows us to remotely control the equipment and monitor critical check points. For this purpose, we have automatized pumping stations, as well as self-regulation mechanisms, depending on the required demand. In addition, we have solenoid valves and humidity sensors installed in the orchard, which are constantly fed with data from a weather station to support the operation and increase efficiency

Irrigation

The irrigation system is pressurized, which improves water use and distribution efficiency. Two thirds of the orchard have a sprinkler irrigation system and the other third has a micro-sprinkler system, which optimizes the distribution of water resources and makes it possible to use up to 90% of the available water.

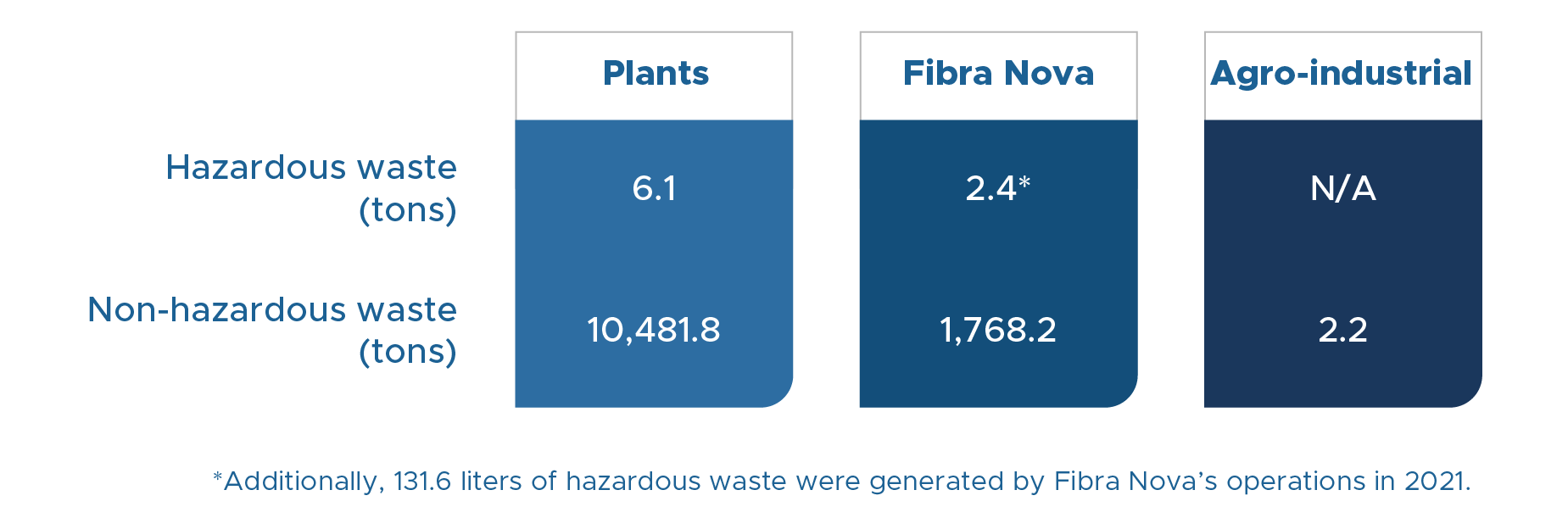

WASTE

At Grupo Bafar, we recognize the importance of developing an adequate waste management process, for this reason we have established procedures for handling both special and hazardous waste generated in our activities.

Special handling waste is disposed of in different containers to separate general waste, cardboard, and plastic, which are then collected by a third party. Each month, we receive sealed manifests that validate the quantities of waste collected.

On the other hand, hazardous waste such as oil, filters, and contaminated tow are stored in a special area at the general warehouse. Access to the area is restricted to authorized personnel who keep strict control of the quantity and type of waste stored. Finally, a third party is responsible for transporting the hazardous waste to disposal.

We are advancing in the collection of information on waste generated in our different business units, which will allow us to deploy a waste management and classification system together with metrics to track our progress on an ongoing basis.

Notes:

- Information as of the end of December 2021.

- Fibra Nova’s waste generation is classified as indirect for Grupo Bafar since it is derived from tenant operations in our properties.

- Includes waste generation for five Fibra Nova’s sites as of the end of October 2021.

- The B-Energy plant generated 12,300 liters of used oil as hazardous waste in 2021.

- The waste generated in the Consumer Products, Retail, and International business units have yet to be measured. However, we are working on the management of information to report this metric in future reports.

- Vextor’s waste generation is included in the plants as they share the same location.

- There is no information on waste generated in the International, Consumer Products and Retail business units; however, we are working on consolidating this information.

1Includes Consumer Products, Retail, International, Agro-industrial, B-Energy, and plants.